Lab Report - Rouge

INTRODUCTION

Rouge is a cosmetics used to apply

color to the cheeks. Modern rouge reparations come in the forms of liquid,

cream and dry solid forms.

OBJECTIVES (POWDER ROUGE)

- To formulate dry powder rouge and cream rouge.

- To formulate cream rouge from 2 commercial

hard lipstick preparations.

- To study the factor affecting color shading in

powder and cream

- To evaluate the effect of storage condition on

the final product

MATERIALS

Basic powder formulations

|

|

Kaolin

|

16%

|

Talc

|

48%

|

Magnesium

stearate

|

6%

|

Zinc oxide

|

5%

|

Rice starch

|

10%

|

Magnesium

Carbonate

|

5%

|

Colorant

(Red101)

|

4%

|

Titanium

diaoxide q.s ad

|

100%

|

PROCEDURES

I.

Powder

rouge

a)

60g of

the basic powder formulation without colouring agent is prepared

b)

Another

60g of powder rouge is prepared containing 4% of an Insoluble red colouring

agent (P4)

c)

The 3rd

60g powder rouge is prepared by diluting the colouring agent up to 3%

d)

Step a) is repeated by using 2 different amount of colouring agents: (2%

and 1%)

Code

|

Colorant (%)

|

Amount of P4

(g)

|

Amount of P0

|

Total amount

of rouge (g)

|

P1

|

4

|

20

|

-

|

20

|

P2

|

3

|

15

|

5

|

20

|

P3

|

2

|

10

|

10

|

20

|

P4

|

1

|

5

|

15

|

20

|

RESULTS

1. Powder

rouge in the dark

Code

|

Colour separation

|

Change in colour

|

Flow properties

|

P1

|

No

|

No

|

Good

|

P2

|

No

|

No

|

Good

|

P3

|

No

|

No

|

Good

|

P4

|

No

|

No

|

Good

|

2. Powder

rouge when exposed to sunlight

Code

|

Colour separation

|

Change in colour

|

Flow properties

|

P1

|

No

|

No

|

Good

|

P2

|

No

|

No

|

Good

|

P3

|

No

|

No

|

Good

|

P4

|

No

|

No

|

Good

|

3. Powder

rouge when test on cheek

Code

|

Duration of application

|

Result

|

P1

|

6 hours

|

No irritation, smooth

|

P2

|

6 hours

|

No irritation, smooth

|

P3

|

6 hours

|

No irritation, smooth

|

P4

|

6 hours

|

No irritation, smooth

|

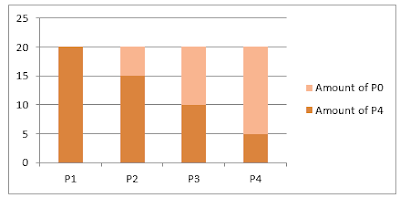

4. Chart

of colour shading of powder rouges

DISCUSSION

According to the Food and Drug Administration, colour additive as

defined by the regulation is any dye, pigment or other substance that can

impart colour to a food, drug, cosmetic or to the human body. Colour additive

is an important component of many products, making them attractive, appealing,

appetizing and informative.

Dyes can be water soluble or

oil soluble. Thus, solubility of dyes in powder or cream rouge is important to

give the colour effect. Water soluble dye gives crisp, transparent colour and

light, clean tints to the opaque products. Oil soluble dye gives a more uniform

and even colour compared to water soluble dyes, especially if it is used in

producing cream rouge.

From the chart of colour shading from the result, the concentration of

the colourant is the one which will determine the colour shadings of powder

rouges. This is because when the greater amount of P4 is added in the

formulation, the darker the shadings of powder rouge will be. P4 is the

formulation that has been added 4% of colourant of the total weight of

formulation meanwhile P0 is the formulation that has no colourant.

Four same amounts (20g) of powder rouges are formed by mixing different

amount of P4 and P0 respectively. The powder rouges are labeled as P1, P2, P3

and P4. P1 has 4% of colourant (20g of P4), P2 has 3% of colourant (15g of P4

mix with 5g of P0), P3 has 2% of colourant (10g of P4 mix with 10g of P0) and

P4 has 1% of colourant (5g of P4 mix with 15g P0).

Powder rouge is the most

commonly used and preferred nowadays, though in compressed one, compared to

cream rouge. There are some differences between powder rouge and cream rouge. Powder

rouge is suitable for those with oily or combination skin because powder rouge

is able to absorb grease for a matte finish. Meanwhile, the individual with a

dry skin needs to opt for cream rouge, which is more emollient in order to

minimize flaking. Powder rouge will give a more finished look and this is

perfect for contouring cheekbones. Cream rouge will give a dewy and outdoorsy

flush. Another great benefit of powder rouge is it can be used as eye shadow as

well and it can last for a day, while cream rouge can be used as lipstick due

to its creamy texture and it gives a soft, long-lasting glow, youthful

appearance.

The ingredients in the powder rouge formulation are kaolin, talc,

magnesium stearate, zinc oxide, rice starch, magnesium carbonate, colourant and

titanium dioxide. Kaolin is a natural clay-like mineral and composed of silica,

iron, magnesium, calcium, sodium, zinc and other minerals. It is a white

insoluble powder which has excellent absorbent properties which is used to draw

out impurities and toxins. It is also an anticaking agent which will helps in

preventing the powder from caking and clumping. Rice starch has the same

absorbent properties as kaolin. Talc is as a lubricant, mattes and hues the

skin. It has an antibacterial effect, hence preventing skin impurities. Magnesium

stearate as a glidant, which is a substance that helps improving the

flowability of powders, in the powder rouge formulation. Zinc oxide acts as a

bulking agent and permits it to cover the skin more thoroughly. Titanium dioxide

imparts whiteness to coloured cosmetics and personal care products that are

applied to the skin (including the eye area), nails and lips. It helps to

increase the opacity and reduce the transparency of a product formulation. It

also absorbs, reflects and scatters light (including ultraviolet radiation),

which can protect the product from deterioration.

To test the stability of products, the

powder rouges have been stored in different conditions, which are exposed to

sunlight and in dark. The criteria that has been look for are the colour

separation, change in colour and flow properties, to know is there any

differences before and after the way to store the powder rouge. After one

month, as stated in the result, there are no differences in colour separation,

colour change and flow properties, which mean that the storage of the powder

rouges either exposed to light or in dark does not results any effect. There is

no colour separation because the preparation of the rouge does not involve any

liquid substances, it was prepared in a completely dry condition from the

weighing, mixing as well as packaging. In addition, the formulation contains

titanium dioxide which absorbs, reflects and scatters light (including

ultraviolet radiation) as mention above. So, the product is protected from

deterioration. Besides, magnesium stearate which is a good glidant is also

incorporated in the formulation. Hence, the powder still has good flow

properties even after a month of storage.

However, it was only tested for one

month, thus some precautions still need to be done like avoid exposing it to

direct sunlight to make sure that the product will not be undergo any chemical

or physical changes throughout the usage before the expiring date.

CONCLUSION

Four

powder rouges have been formulated by modifying the

concentration of the colorant and are labeled as P1, P2, P3 and P4. The concentration of colourant is the one which will

determine the colour shadings of powder rouges. The greater the concentration

of the colorant, the darker the colour shadings of the rouge will be.

Meanwhile, the storage conditions are very important towards the product

stability. Exposure to sunlight may cause separation of colorant, bad flow

properties and change in colour. However, throughout this experiment, the storage

conditions do not affect the stability of the powder rouges.

REFERENCES

2.

Julie,

N. B., Arthur, L. L. & Catherine, J. B. 2003. Color Additives: FDA's

Regulatory Process and Historical Perspectives.

http://www.fda.gov/ForIndustry/ColorAdditives/RegulatoryProcessHistoricalPerspectives

http://www.fda.gov/ForIndustry/ColorAdditives/RegulatoryProcessHistoricalPerspectives

3.

Gio.

2015. Cream VS Powder Blush: Which is better?.

http://www.beautifulwithbrains.com/better-cream-powder-blush

http://www.beautifulwithbrains.com/better-cream-powder-blush

4.

Anon.

2002. Better Blush How-tos.

http://www.cosmopolitan.com/style-beauty/beauty/how-to/a107/better-blush-how-tos

http://www.cosmopolitan.com/style-beauty/beauty/how-to/a107/better-blush-how-tos

Comments

Post a Comment