Cosmeceutical Lab Report - lipstick

Introduction

Lipsticks

is a cosmetic product that exist in different types and colours. As with most

types of makeup, lipstick is typically worn by women. Some lipsticks are in the

form of lip balms, to add colour and provide hydration. Lipstick formulations

are most widely used to enhance the beauty of lips and to add glamour touch to

the makeup. Lipstick provide a convenient means of either freshening a makeup

by colouring or protection of lips from the effects of cold, dry weather, UV

light and wind.

Lipstick contains wax, oils, antioxidants and

emollients. Wax provides the structure to the solid lipstick. Lipsticks may be

made from several waxes such as beeswax, ozokerite and candelilla wax. Due to

its high melting point, Carnauba wax is a key ingredient in terms of

strengthening the lipstick. Various oils and fats are also used in lipsticks,

such as olive oil, mineral oil, cocoa butter, lanolin, and petrolatum.

In

the early period, lipsticks of limited colours were produced such as red. But now,

there are lipsticks of various colours such as pink, orange, violet and even

black. Some lipstick contain

something called "pearl essence".

This silvery substance can be found in fish scales. It is primarily sourced from herring and can be found

in many lipsticks, nail polishes and

other cosmetic products due to the shimmer effect it creates.

Objective

The objectives of this experiment are to ensure

that the students able to:

1.

Differentiate

the different function of the ingredient in each formula.

2.

Understand

the rational and function of the different type of formulation of the lipstick.

3.

Evaluate

the equality of the product.

Apparatus

1. Evaporating dish

2.

Water bath

3.

Electronic balance

4.

Weighing boat

5.

Glass rod

6.

Thermometer

7.

Measuring cylinder

Materials

1.

Castor oil

2.

D&C red

pigments

3.

Mica

pigments

4.

White

beeswax

5.

Cocoa

butter

6.

Vitamin E

acetate

7.

Vaseline

8.

Honey

9.

Paraben

(0.1% methyl paraben solution)

Methodology

1. There are four different lipstick

formulations prepared by varying amount of Phase A, the colour of the lipsticks.

2. Firstly, 15mL of Castor oil

was measured and put into evaporating dish on water bath. 0.5g of D&C red

pigments and 0.5g Mica pigments were then added accordingly. The mixture of

colour dispersion was stirred until homogenous. Temperature was checked

regularly to prevent overheating. (Phase A)

3.. Meanwhile, solid of 1.7g

White beeswax was melted on the water bath together with Vaseline. The mixture

was stirred until there was no presence of solid particle. Cocoa butter,

vitamin E acetate, honey and drops of paraben were added and the mixture was

continuously stirred. (Phase B&C).

4. Finally, the two mixtures were

removed from heat. Colour dispersion was added into the mixture of ingredients

and stirred gently until the final product was achieved.

5. The final product was then

poured into a mould and let cool before being sealed.

6. For the other three lipstick

preparations, some changes in the quantities of the ingredients were made:

Lipstick 2: 0.4g

D&C red pigment and 0.6g Mica pigments were used.

Lipstick

3: 0.3g

D&C red pigment and 0.7g Mica pigments were used.

Lipstick

4: 0.1g

D&C red pigment and 0.9g Mica pigments were used.

RESULT

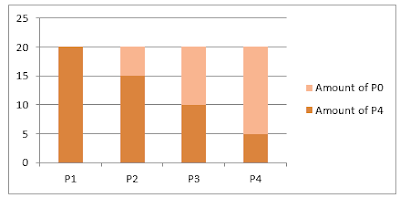

Chart

of colour shading of all formulations

formulation 3

formulation 4

formulation 4

Formulation

1

Phase

A

|

Phase

B

|

Phase

C

|

15mL

Castor oil

|

1.7g

White beeswax

|

3

drops Paraben (0.1% methyl paraben solutions)

|

0.5g

D&C red pigment

|

1.0g

Cocoa butter

|

|

0.5g

Mica pigments

|

1.3ml

Vitamin E Acetate

|

|

0.5g

Vaseline

|

||

0.6ml

Honey (for taste)

|

Formulation

2

Phase

A

|

Phase

B

|

Phase

C

|

15mL

Castor oil

|

1.7g

White beeswax

|

3

drops Paraben (0.1% methyl paraben solutions)

|

0.4g

D&C red pigment

|

1.0g

Cocoa butter

|

|

0.6g

Mica pigments

|

1.3ml

Vitamin E Acetate

|

|

0.5g

Vaseline

|

||

0.6ml

Honey (for taste)

|

Formulation

3

Phase

A

|

Phase

B

|

Phase

C

|

15mL

Castor oil

|

1.7g

White beeswax

|

3

drops Paraben (0.1% methyl paraben solutions)

|

0.3g

D&C red pigment

|

1.0g

Cocoa butter

|

|

0.7g

Mica pigments

|

1.3ml

Vitamin E Acetate

|

|

0.5g

Vaseline

|

||

0.6ml

Honey (for taste)

|

Formulation

4

Phase

A

|

Phase

B

|

Phase

C

|

15mL

Castor oil

|

1.7g

White beeswax

|

3

drops Paraben (0.1% methyl paraben solutions)

|

0.1g

D&C red pigment

|

1.0g

Cocoa butter

|

|

0.9g

Mica pigments

|

1.3ml

Vitamin E Acetate

|

|

0.5g

Vaseline

|

||

0.6ml

Honey (for taste)

|

Evaluation

of lipsticks

1. Melting

point test

This test is done by

placing a small quantity of lipstick of the four lipstick formulation (1,2,3

and 4) into an evaporating dish. Then, the lipstick is then heated on a water

bath for even heating. The time taken at which the lipstick started to melt was

recorded.

Observation: The product

melts.

Tests

|

Formulation

1

|

Formulation

2

|

Formulation

3

|

Formulation

4

|

Melting

point test (time taken to melt at constant temperature of 600C) /

minutes

|

2

min 8 sec

|

2

min 2 sec

|

2

min 7 sec

|

2

min 7 sec

|

2. Stability

test

Condition (texture) of lipstick when

put under different temperature (°c)

LIPSTICK

FORMULATION

|

AT

4°C

|

AT

28°C

|

AT

40°C

|

1

|

Hardened

|

Soft

semi solid, normal

|

Starts to melt, become oily and

sticky

|

2

|

Hardened

|

Soft

semi solid, normal

|

Starts to melt, become oily and

sticky

|

3

|

Hardened

|

Soft

semi-solid, normal

|

Starts to melt, become oily and

sticky

|

4

|

Hardened

|

Soft

semi-solid, normal

|

Starts to melt, become oily and

sticky

|

DISCUSSION

In

this experiment, we prepared four different formulations and shades of

lipstick. Each formulation has three phases which are Phase A, Phase B and

Phase C. Phase A is the preparation of colour dispersion while Phase B is the

preparation of wax base which involves the blending of oils and Phase C

involves the adding few drops of methyl paraben solutions. Paraben is used as a

preservative is most cosmetic products to prevent bacterial growth.

For

this formulation, we have decided to not do any changes on phase B and C. This

is because any unsuitable alteration to them may lead to hardness or the

lipstick becomes too soft. We only varied the amount of ingredients in Phase A to

produce 4 different shade of lipstick.

To

ensure the lipsticks are of good quality, several tests were applied on the lipsticks

which are melting points test, and stability test at 4°C, 20-25°C and 30-40°C.

For the melting point test, we took half of the lipsticks from each container

and put into the porcelain glass and heat it at 60°C. The time taken when the

lipstick started to melt was recorded.

For

stability test, we recorded the observation after placing the lipsticks under

several conditions. At normal room temperature which is 20-25°C, all of our

lipsticks are in normal state. There were no changes on the lipsticks and the

colour remains the same. At 4°C, all our lipsticks were placed in a beaker

containing ice and the result was obtained where all the lipsticks remain

unchanged and harden with the appearance of water droplets. For the stability

of lipsticks at 30-40°C, the lipsticks were left under the hot sun. As the

result, all the lipsticks start to melt. They also became oily and sticky.

There

were also some errors we had done while preparing the lipstick formulations.

The first one, was, while conducting the preparation of all the lipstick

formulations and stability tests, parallax errors might be done, contributed to

the inaccuracy of the results. Besides, we could not fix the temperature of the

water bath. Therefore, it was difficult for us to constant the temperature at

60 ºC

These

are the ingredients that have been used in our lipstick formulations: castor

oil, D&C red pigments, Mica pigments, white beeswax, cocoa butter, Vitamin

E acetate, Vaseline, Honey which was used as flavouring, and Parabens. Each of

them has their own function to produce a good lipsticks product.

Ingredients

|

Functions

|

Castor

oil

|

|

Mica

pigments, D&C red pigments

|

|

White

beeswax

|

|

Cocoa

butter

|

|

Vitamin

E acetate

|

|

Vaseline

|

|

Parabens

|

|

CONCLUSION

At

the end of the practical, our group members have gained more knowledge on

lipstick preparation through this experiment. We were able to differentiate the

different functions of each ingredient in the formula and evaluate the quality

of our products.

In order to prepare the lipsticks, we have

performed the required procedures correctly to obtain a quality product. The

average time for the lipstick to melt at 60ºC was 2 minutes 1 second. The

lipsticks appeared to be in liquid form at 40ºC and above, stabled at room

temperature and hardened at 4ºC. Based on the chart of colour shading, we can

conclude that different amount of pigment gives different shade to the

lipstick.

REFERENCES

- Mishra,

P., &Dwivedi, S. 2012. Formulation and Evaluation of Lipstick

Containing Herbal Ingredients. Asian J. Med. Pharm. Res, 2(3),

58-60.

- Formulation

and Evaluation of Natural Lipstick from Coloured Pigments of Beta Vulgaris

Taproot. 2014. SwethaKruthika V*,

S Sai Ram, ShaikAzhar Ahmed, ShaikSadiq, Sraddha Deb Mallick, and T

RamyaSree.Journal of Pharmacy and Pharmaceutical Sciences.

Comments

Post a Comment